Responding World-Wide

It’s no accident that Munson Response Boats are currently in use by hundreds of the world’s leading marine spill response organizations. We offer a full range of pollution control vessels that are adaptable to numerous marine spill scenarios. Bill Munson’s original landing craft design was developed over 40 years ago as a multi-purpose oil spill response platform.

It’s no accident that Munson Response Boats are currently in use by hundreds of the world’s leading marine spill response organizations. We offer a full range of pollution control vessels that are adaptable to numerous marine spill scenarios. Bill Munson’s original landing craft design was developed over 40 years ago as a multi-purpose oil spill response platform.

The Munson landing craft design is one of the most effective vessels at performing the many tasks that an oil spill presents. Without quick & effective oil spill response, our coastlines would be in much greater peril. The brave men and women that do battle with these unfortunate occurrences, along with their specialized equipment and know-how, are the last line of defense against the potentially devastating effects of a spill.

Our clients say it best…

“It is hard to believe that this 42-boat, 4-year project is coming to a close with the delivery of the final 10 boats this year.”

Model: 23-16 OSR

Poplar Bluff, MO: The 23' Munson Packcat Catamaran makes a great OSR platform. Its small size is offset by the spacious working deck, excellent stability, and carrying capacity. The Missouri Department of Natural Resources uses their Munson OSR for HAZMAT cleanup and other emergency response on lakes and rivers. If you are looking for a trailerable cleanup boat, look no further than the 23' Munson Oil Spill Response Series.

Specifications

Model: 26-1 OSR

Theodore, AL: Response Resources provided oil spill response management support to the BP demobilization and decontamination effort in Mississippi, Alabama, and Florida. Four Bayou Responder OSR's paired with Munson recovery barges are at work in the gulf. Special features include tow protection screens, under gunnel storage shelves and large push knees. Flood lighting on the deck let the vessels operate 24 hours a day.

Specifications

Model: 26-29 OSR

Richmond, CA: The Chevron Texaco refinery in Richmond operates a fleet of five Munson boats including the Osprey. When an oil tanker arrives, it is immediately surrounded by containment boom to protect the surrounding waterway in the event of an incident. A transom engine bracket was installed to increase the cargo deck. A removable boom roller assists the crew in retrieving the boom.

Specifications

Model: 26-34 OSR

North Pole, AK: Alyeska Pipeline operates a pair of these 26’ Responder Class jet boats on the Yukon, Tanana and Copper Rivers. The shallow vee hull design allows the boats to operate in 1 foot of water. A Marine Power 430 HP V8 and Hamilton 241 jet provide plenty of power for towing in river currents. The center console T-top is outfitted with a canvas enclosure and forced air cabin heat. Additional outfitting includes flip-up deck seating, 12V washdown pump, tow post, and fuel transfer system with 12’ hose and nozzle for refueling smaller vessels.

Specifications

Model: 28-3 OSR

Endicott, AK: Alaska Clean Seas protects the environment by providing effective response services to the Alaska North Slope Crude Oil Producers. OSR Endeavor is assigned to the BP operations and is tasked with transporting equipment, personnel, and boom deployment for near shore response operations. Special arctic features include storm covers for cabin windows and forced air cabin heat. Bow push knees are designed to align with those on recovery barges.

Specifications

Model: 28-16 OSR

Nationwide, USA: The Marine Spill Response Corporation is the largest, dedicated oil spill and emergency response organization in the United States. They operate forty-two Munson boats as trailerable oil spill response vessels. These boats are equipped with adjustable push knees that allow for pushing oil skimmers and barges. Each transom has been fitted with round corners for increased maneuverability while backing.

Specifications

Model: 30-10 OSR

Linden, NJ: On any given day, the ConocoPhillips' Bayway Refinery can process up to 238,000 barrels of crude oil from its plant alongside the New Jersey Turnpike in Linden. It's a tradition that goes back more than 100 years, to when John D. Rockefeller built the place. The refinery incident response team's Munson supports spill response and cleanup efforts. A crane hoists the vessel into the water using its four-way lifting eyes.

Specifications

Model: 30-31 OSR

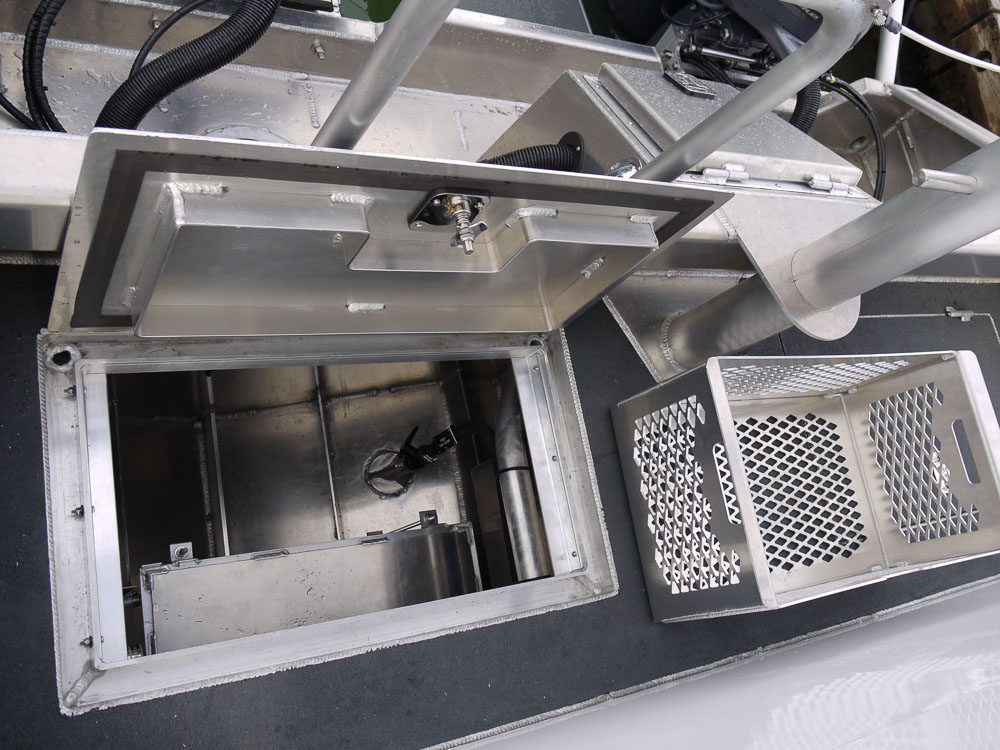

Burnaby, BC: Western Canada Marine Response Corporation maintains an extensive inventory of the most sophisticated spill response equipment available today. It is their mandate to ensure preparedness and protection during oil spills and environmental incidents. Burrard Cleaner No. 4 is the latest addition to their fleet. The wheelhouse is equipped with seating for four and a concealed portable head. Special locker inserts take advantage of under deck space for storage.

Specifications

Model: 32-6 OSR

Wainwright, AK: The Umiaq Corporation operates the M/V Neakok Island in support of their onshore contingency response program contract with Shell Oil in the Chuckchi Sea. Designed to support hydraulic oil skimmers, the Neakok Island is outfitted with redundant PTO-driven hydraulic pumps. A hydraulic planetary deck winch is used to load equipment on to the forward deck and hydraulic lines are routed to the bow to allow the easy connection of skimmers and other equipment.

Specifications

Model: 34-4 OSR

Richmond, CA: When an oil tanker arrives at the Chevron Texaco refinery in Richmond it is immediately surrounded by containment boom to protect the surrounding waterway in the event of an incident. When a tanker arrives the Wharf Raider 1 deploys containment boom by backing around the ship. Special round corners were incorporated into the transom to provide more control while vessel is in reverse. A removable hydraulic boom roller assists the crew in retrieving the boom.

Specifications

Model: 34-40 OSR

Stevens Village, AK: Stevens Village is a small, remote settlement along the Yukon River, in Central Alaska. Their 34’ Munson landing craft, the “Stevens Village Responder”, operates as an oil spill response vessel for the TransAlaska Pipeline. Outfitting includes a hydraulic boom reel, tow post, engine guard, push knees, side doors, lifting davit, washdown pump, LED deck lights, deck winch, cabin heat, and 12V fuel transfer pump for refueling small craft.

Specifications

Model: 34-50 OSR

St. Ignace, MI: Built in 1953, Enbridge Pipeline travels deep under the Straits of Mackinac for 4.5 miles, and has never experienced a leak in more than 65 years of operation. A pair of these 34’ Munson response vessels stand by in the event of a spill or fire. Each vessel is outfitted with a portable Munson “Fire Ant” self-contained skid mounted 500 GPM fire pump to allow the fire pump system to be quickly removed/installed on the main deck when needed. Additional outfitting includes port & starboard side doors, push knees, tow post, engine guard, Onan 5kw generator, Dometic air conditioner, Garmin electronics, and twin Mercury 300’s mounted on hydraulic jack plates.

Specifications

Model: 35-2 OSR

Lagos, Nigera: Exxon Mobile Bonny River Petroleum Terminal services East Area offshore petroleum drilling rigs. Committed to environmental protection and safety, the Exxon Bonny River terminal operates an extensive fleet of incident response equipment. OSR 1 is responsible for boom deployment and the transport of hazardous waste. A hydraulic deck crane allows the transfer of 55 gallon drums from the deck to shore.

Specifications

Model: 35-16 OSR

Portland, OR: NRC has responded to thousands of marine and land-based oil spill incidents around the globe and maintains stockpiles of oil spill equipment around the US and internationally for immediate response. FRV Next Generation is staged in Portland for immediate deployment on the Columbia River and Oregon Coast. The wheelhouse features an enclosed head compartment and a four person work table. Wheelhouse glass is wire reinforced for towing protection.

Specifications

Model: 38-14 OSR

El Segundo, CA: The Chevron El Segundo Refinery is the largest refinery on the West Coast. Its Offshore Marine Terminal is located 1.5 miles from land and is connected via underwater pipelines. The M/V Walt K is a dedicated oil spill response vessel responsible for protecting beaches and wildlife. A Lamor LPP6 HA/75C diesel power pack provides power for running oil skimmers and equipment. Two 4' x 6' under deck holds are installed on the foredeck for storage of equipment. The elevated cabin is outfitted with seating for 4 passengers. Additional outfitting includes a MaxiLift 110 telescoping boom crane and port & starboard side dive doors.

Specifications

Model: 38-28 OSR

Burnaby, BC: Western Canada Marine Spill Response Corporation operates a small fleet of Munson Boats, including four of these 38’ catamarans. Outfitting includes a heated cabin, pilot & co-pilot suspension seats, head compartment, tow post, engine guard, boom pen, davit with 12V windlass, port & starboard side doors and Raymarine radar/plotter/sounder with AIS.

Specifications

Model: 40-10 OSR

Ras Tanura, Saudi Arabia: Saudi Aramco's Ras Tanura Terminal is one of the world's largest crude oil terminals with a complex of four man-made Sea Islands interconnected by walkways. Their 40' landing craft is used as an offshore pipeline and elevated trestle workboat. Outfitting includes a 1.5-ton capacity hydraulic A-frame and two 2-ton capacity boom cranes. The elevated control station provides visibility over large cargo loads.

Specifications

Model: 40-11 OSR

El Segundo, CA: The Chevron El Segundo Refinery is the largest refinery on the West Coast. Its Offshore Marine Terminal is located 1.5 miles from land and is connected via underwater pipelines. The M/V J. Skara is a dedicated oil spill response vessel responsible for protecting beaches and wildlife. A Lamor LPP6 HA/75C diesel power pack provides power for running oil skimmers and equipment. Two 4’ x 6’ under deck holds are installed on the foredeck for storage of equipment. The elevated cabin is outfitted with seating for 4 passengers. Additional outfitting includes a MaxiLift 110 telescoping boom crane and port & starboard side dive doors.

Specifications

Model: 48-5 OSR

El Segundo, CA: The Chevron El Segundo Refinery is the largest refinery on the West Coast. With such a close proximity to beaches and wildlife they are committed to environmental protection and responsibility. The M/V Duke J is deployed as part of their incident response program. A hydraulic boom reel on the aft deck is used to deploy and retrieve 1200 feet of offshore containment boom. Hydraulic controls on wheelhouse flybridge provide the boom operator an unobstructed view of the aft deck.

Specifications

Model: 48-12 OSR

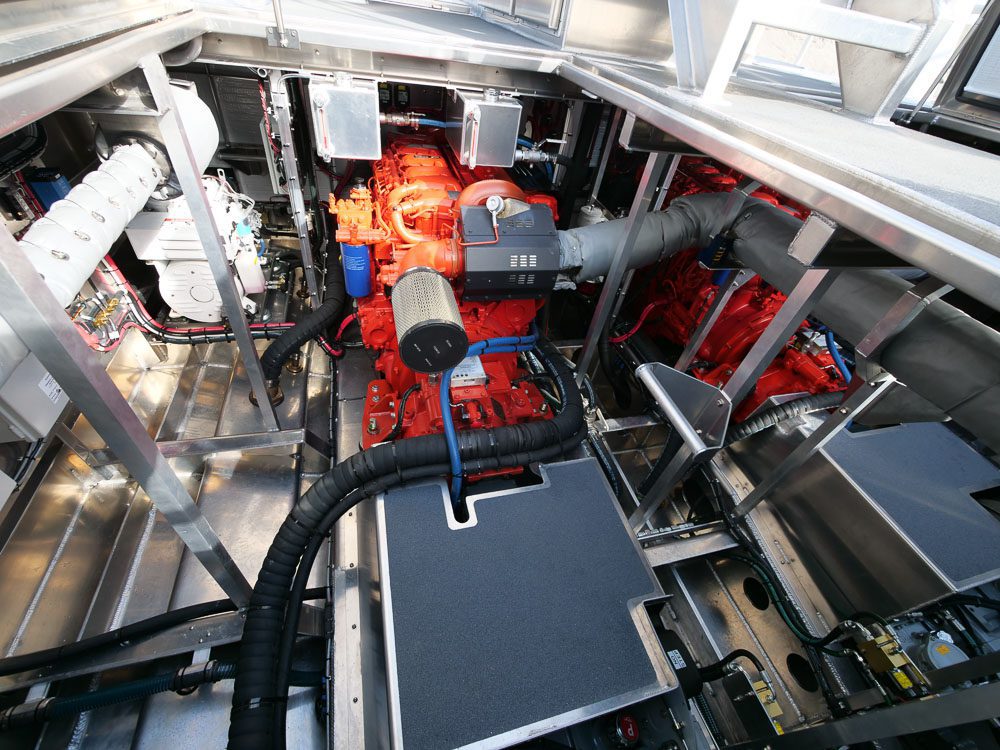

Prudhoe Bay, AK: Located 400 miles north of Fairbanks, on Alaska’s north slope, Prudhoe bay is home to the largest oil field in North America. The 48’ “Pt. McIntyre” is a purpose build oil spill response vessel designed to retrieve oil in the event of a spill in order minimize the environmental impact. Outfitting include keel cooling with dry exhaust for both the main engines and the generator, Glendenning’s controls with joystick piloting system, a integrated hydraulic system rated for 100GPM @ 3700PSI, dual Maxilift hydraulic deck cranes, bow and stern hydraulic capstans, bow and stern hydraulic anchor winches, hydraulic quick disconnects for oil skimmers and a boom roller, as well as an enclosed wheelhouse with electric and heat exchanged main cabin heat.

Specifications

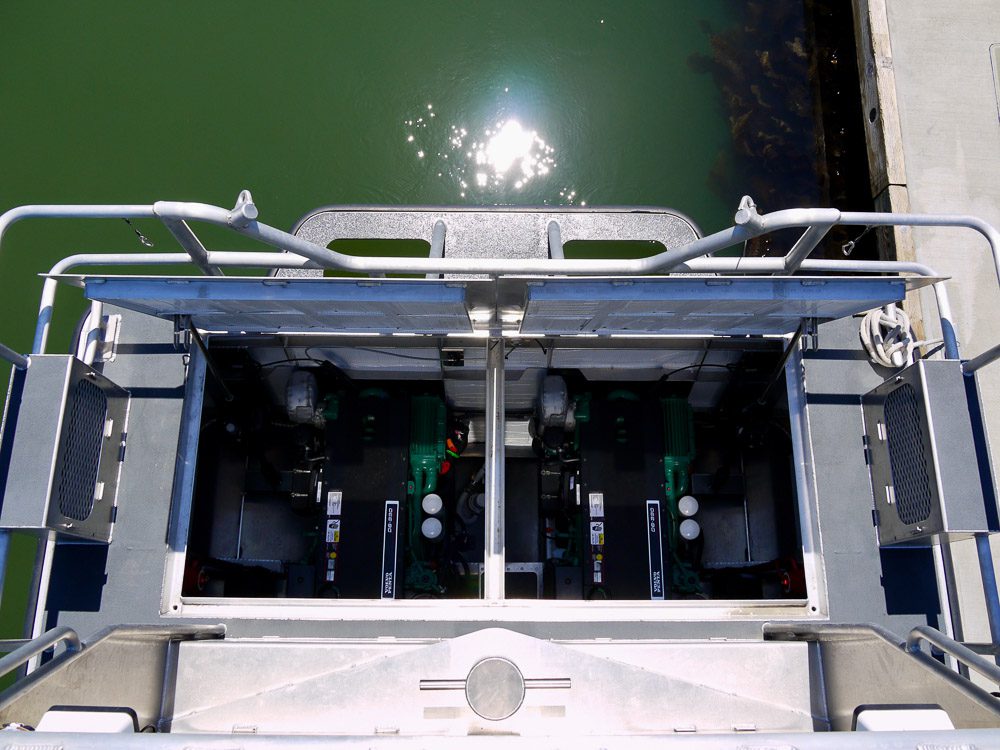

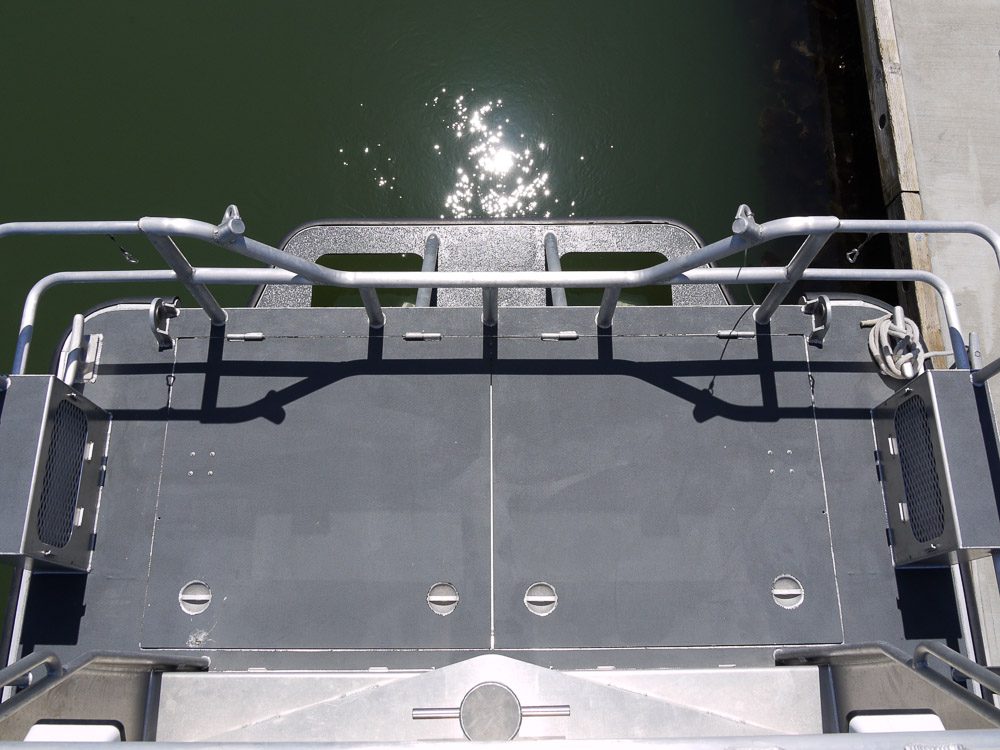

Model: 52-5 OSR

Sydney, BC: WCMRC is the only Transport Canada-certified marine spill response organization on Canada’s West Coast. WCMRC operates a small fleet Munson Boats including four of these 52 footers which are powered by twin 750 HP Scania diesels with Fernstrum closed loop keel coolers. Twin Hamilton 403 jets are operated with Glendinning Complete Controls 2 system with joystick piloting for precise maneuvering. Additional outfitting includes a bow control station, Maxilift ML330.4H deck crane with wireless controls, interceptor trim tabs, 3M vinyl wrap and Sonihull ultrasonic antifouling system.

Specifications

Our clients say it best…

“It was a pleasure visiting with you and Jon today to observe the progress of MSRC’s workboats. It is hard to believe that this 42-boat, 4-year project is coming to a close with the delivery of the final 10 boats this year. From my prospective, as MSRC’s program manager for this major boat building project, it has been an exceptionally well executed project and it has been a personal pleasure for me to work with Bill, Jon and yourself during the last 4 years.”

Doug – Technical Services Manager

Marine Spill Response Corporation